|

|

|

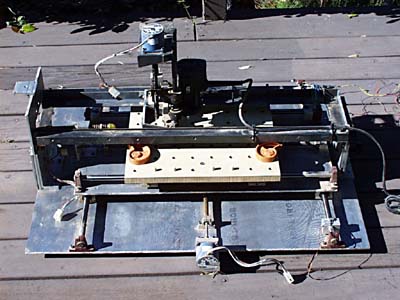

Macintosh Wood Router

|

CNC table for routing wood or metal with a Macintosh

These pages were assembled to sell a tool on eBay. The tool sold in December of 1998, but these pages remain as a description of a very complete homemade CNC router and what it could do. I have replaced this tool with a computerized full size vertical mill.

This table is a home built tool for hooking up to a personal computer. Complete software is included for Macintosh users. It has three axes of motion. The work is clamped to the wooden hold-down area and stepper motors move it in two directions. A small laminate trimmer router is held in the Z axis and can be raised or lowered. This is an excellent start for hobbyist CNC machining.

Description:

- 28" x 35" base plate of 1/4" aluminum

- 16" x 16" work surface

- 11" x 11" travel in X and Y

- (4) lengths of precision shafting, 5/8" diameter and 28" long

- (8) Thompson Super Pillow Block linear ball bearings, model SPB-10 OPN

- (3) SlowSyn stepper motors model M061-FC08, 1.25 volts, 3.8 amps, 35 oz/in torque

- (6) limit switches mounted on moveable blocks

- laminate trimmer router with 1/4" collet

- variable speed controller for the router

- power supply and motor drivers with logic level (parallel port) step and direction input

- Software and interface for Macintosh computers to cut shapes drawn in Adobe Illustrator

- Macintosh program to drive a small CNC lathe with the same interface. I developed this tool for use with a Macintosh computer. It will work fine with Windows or DOS, but you will need software to output step and direction commands to the parallel port.

Also available is a wooden enclosure with hinged glass door which keeps noise and chips contained. This enclosure is too big to ship, and will be included at no cost if the buyer is able to pick it up in Santa Barbara, California.

I have used this tool mostly to cut wood, but also brass. Small diameter end mills are held in the 1/4" collet of the router. Speed can be controlled from about 20,000 RPM to a few hundred.

Click here to see details of the tool and software, with additional pictures of the table and work created with it.